While modern Direct Injection engines produce more power, while also being more fuel efficient and cleaner running, the trade-off is that the intake valves are no longer constantly cleaned by fuel rich air. This had made the cleaning / blasting of these valves a necessary maintenance item. While exact numbers for time-frame or miles until needed are not standard, most DI cars could see improvements every 50K or sooner.

Using this kit and a Harbor Freight Portable Blaster Kit, it is possible to do the job for about $50 in parts that can be reused each time and a few dollars of walnut blast media.

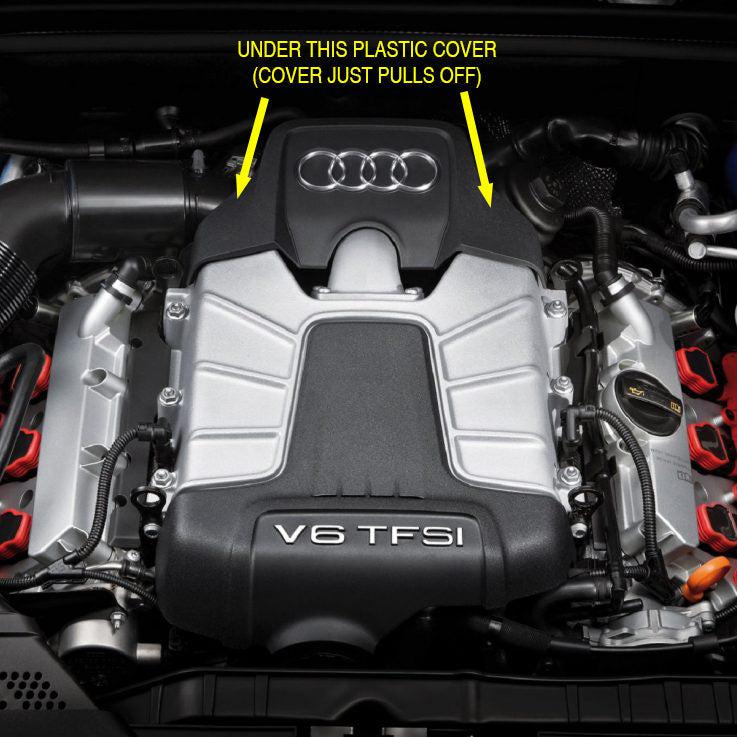

The supercharger and lower flaps must be removed and this is put onto a CLOSED intake port (meaning that the valves on that specific port are closed). To close each port's valves one at a time, use a wrench on the crack pulley to turn over the engine manually. While grit is blasted into one hole, the other connects to a vacuum to suck the grit out at the same time. Just move the nozzle around at different angles to hit all the walls of each port.

Our personal vehicle saw a tremendous change once cleaned as shown in the photos. The valves closest to the firewall seem to always look the worst on these cars. If there is a port or side that is significantly worse than the others, a supercharger intercooler might have a leak.

While the supercharger and flaps are off, it is a great time to install a Phenolic spacer kit.

Standard shipping charges will apply to the rest of the world.